Automotive & Transit

Accelerating Durability and Optical Clarity

Every glass or plastic surface that’s exposed to damage or wear needs a protective coating.

Get the ideal coating for every application.

Use SDC coatings to resist abrasion, impact, chemical or UV radiation damage to glass and plastic while maintaining excellent optical clarity. They provide premium weatherability and outdoor durability, and will not discolor with exposure to sunlight.

Our subsidiary COTEC GmbH also offers metallization surface treatments for automotive headlights and reflectors.

Our tailored coatings cover vital parts on all kinds of transportation.

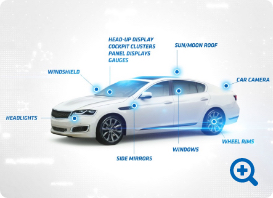

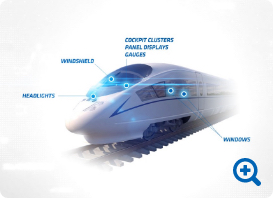

APPLICATIONS FOR ALL VEHICLE COMPONENTS

Our innovative, patented transportation vehicle applications include all exposed surfaces in cars, trucks, motorcycles, planes, boats, trains, buses, and motor coaches.

Vehicle Parts:

Windows, side mirrors and camera systems, windshields and windscreens; canopies, lights, sun/moon roofs, cockpit instrument clusters, panel displays, and gauges.

Electronics:

Digital cockpit instruments, panel displays, and gauges, Head-Up Displays (HUD), GPS navigation devices and systems, LED lighting.

CRYSTALCOAT® FOR MULTIPLE SURFACES

Our optically clear, premium CrystalCoat multi-purpose surface glazing treatments and weatherable coating system increase the durability of enclosed shelters for trains, trams, taxis, and bus stops.

ANTI-FOG APPLICATIONS

Our subsidiary, FSI Coating Technologies, also offers a wide range of complementary anti-fog coating and film solutions for automotive and transit applications.

Solutions for all substrates

Glass: insulated, laminated, safety, security, or specialty bulletproof and tinted

Polycarbonate, acrylic and other plastics, with primer-free adhesion (best-in-class abrasion resistance for polycarbonate substrates)

Aluminum and other non-ferrous metals

Manufacturing advantages

Excellent resistance to abrasion, impact and chemical damage

Premium weatherability and outdoor durability

Protection against UV radiation preserves exceptional optical clarity with no discoloration due to exposure to sunlight and saves energy through lower temperature variance requirements for heating and cooling

Available in thermal and UV-cure, for dip and flow applications

Functional benefits

May be cleaned with common household ammonia-free glass cleaner

Resistant to oil, dirt, and corrosion, eliminating the need to polish chrome finishes

Exceptional product quality and stability, streamlining and maximizing product yields by reducing the need for frequent tank change-outs

QUESTIONS?

Our senior chemists and technical support staff are dedicated to supporting all your coating and process needs.